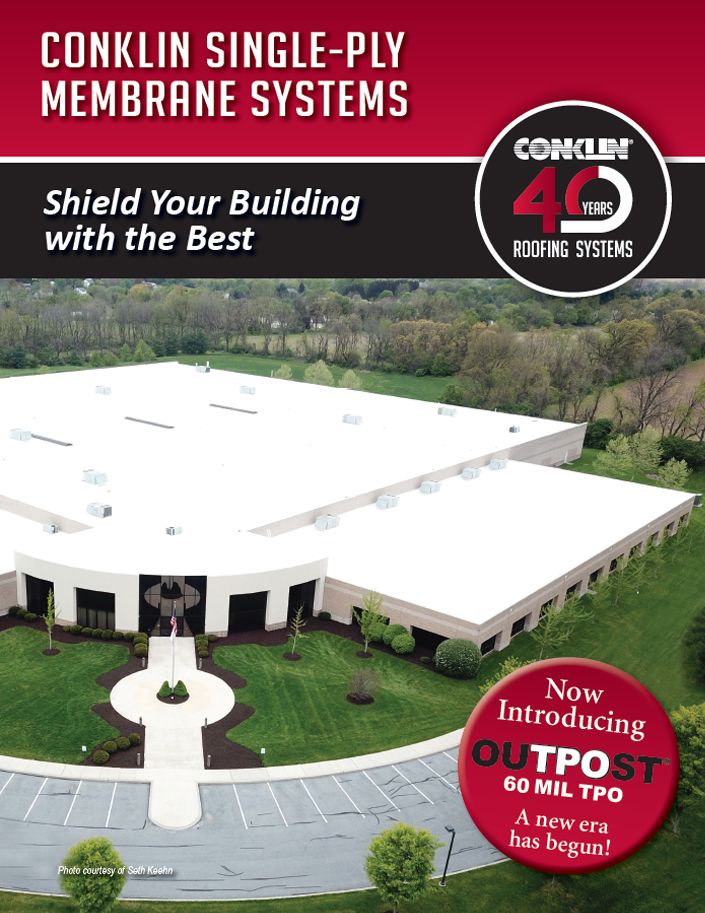

TPO roofing might be something you’re familiar with if you’ve ever seen a brightly white roof. TPO roofing is the most commonly used roof type for commercial buildings. TPO also offers one-ply membrane roofing that has the best energy savings!

What is TPO Roofing and how does it work?

Thermoplastic Polyolefin single-ply roofing is one of most rapidly-growing commercial roofing options. TPO roofing systems include a single layer synthetics and reinforcing scrim that can be used as a flat-roof covering.

TPO membranes may be purchased in sheets 10-12 or 20-foot wide. The sheets are then rolled up, and then taken to the commercial establishment.

TPO roofing has gained acceptance from the industry thanks to its natural reflective finish that blocks UV rays. The National Roofing Contractors Association reported that TPO makes up approximately 40% of the commercial roofing market.

TPO Roofing Installation

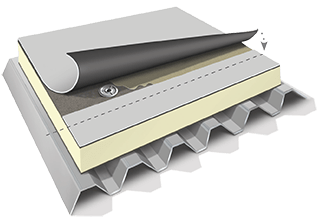

After the substrate has been prepared, the insulation can then be installed. There are many types and options available to the facility manager/owner:

- Polyisocyanurate– Polyiso is the most commonly used insulation type in roofing applications. However, it’s more costly but has a higher rating for R-value.

- Expanded Polystyrene– This insulation is ideal for roofing, wall, or floor applications. It has the highest Rvalue per dollar. EPS can also be used to contact the ground and doesn’t retain water.

- Extruded Polystyrene (XPS) . XPS, which is usually defined by the use of blue, green or pink colors, falls somewhere between EPS, Polyiso, and EPS in terms price and performance. Semipermeable XPS has a perm score of 1.

TPO membranes can either be mechanically or bond to the board. Once the membrane has been rolled out, contractors return to join the seams with a hot gun.

What is single-ply membrane roofing?

Single-Ply Membranes, which are made from rubber and other synthetics, can be ballasted or mechanically fastened to insulation. This creates a layer of protection in your commercial facility.

Single Ply Membrane Roofing may be the most widely-known type of commercial roofing material. But there are other options that will suit your budget and facilities.

There are two main types single-ply commercial roofing materials: Thermoplastic Polyolefin and Ethylene Propylene Diene Terpolymer.

They vary in chemical makeup, installation, and energy efficiency.

TPO roofing has many advantages

A commercial single-ply membrane roof will last for 30 years if it is properly installed and maintained. Single-ply membrane roofing systems offer many other benefits.

- Customers Choice of Insulation – Single-ply membrane roofing doesn’t include insulation, so customers have more options for insuring their roof.

- Class-A Fire-Rated –TPO membranes or EPDM can be listed underwriters Laboratories’ (UL) Class-A fire resistance lists by adding fire retardant chemicals to the manufacturing process.

- Retentive or Reflective –TPO generally is white and highly reflective. EPDM, which is a natural dark-colored membrane, is sometimes called “Black Roofs”.

How can a TPO roof be repaired?

TPOs will last for approximately 15-20 years. The membrane can crack, rupture, fail flashings, and become punctured during this period. This will lead to a roof leak.

Water leaking into a TPO roofing structure is the first sign that it needs to be repaired. This is usually due to water entering the roofing insulation through a leaking seam.

When insulation is saturated with water, it can enter your roof deck and cause leakage on your inside.

This is the time to contact a commercial roofing contractor for a roof inspection.

A roofing contractor will be able tell you:

- Water entering your insulation from the places where it is most likely

- How old is the TPO roof?

- How many layers does the roof have?

- How well are the seams in?

This conversation will reveal the options available to repair the building. Let’s say the roof is 12 year old and the seams have been slightly lifted.

The seams on this roof are close to failure. If you don’t do something now, or very soon, with each wind gust, seams will separate further, allowing more water into the insulation.

An infrared inspection will be performed by a roofing contractor to determine the level of insulation saturation.

About 30 minutes after the sun sets, they will be on your roof. The roof’s surface will be cooler than any water in your insulation at this time.

The contractor will mark the areas with spray paint using the infrared camera.

If your TPO roof is less than 25% saturated, you have repair options

The roof’s saturation level will be determined after the infrared survey. A silicone roof restoration membrane system can be used if your roof is less than 25% saturated.

What happens during a silicone restoration membrane install?

- The areas that are saturated will be removed and replaced by similar material

- The entire roof field will be power washed, and cleaned

- The seams of TPO’s roof will be reinforced and strengthened

- The roof will then be coated with silicone.

- A new 10- to 20-year warranty will then be issued